A floating power station has high requirements for the corrosion resistance of a floating PV system, especially in extreme application scenarios such as high salt, high humidity, high temperature and high cold, which faces the most severe corrosion environment challenges. Sungrow Floating PV has long-term cooperation with many universities and marine research institutes to carry out anti-corrosion technology research of floating PV system, and innovate and develop a system anti-corrosion composite coating scheme to effectively solve the anti-corrosion problem.

High Corrosion Resistance

According to the characteristics of the actual corrosion service environment, the anti-corrosion structure of the Sungrow Floating PV system is designed. The high corrosion-resistant metal coating material is used to match the composite coating. The corrosion resistance effect passes the worst CX environment test and assessment to ensure that the product has excellent salt spray resistance, acid and alkali resistance, water resistance and solvent resistance. The anti-corrosion design structure has been put into the actual sea area for 18000 h +, and it is still in the continuous actual sea assessment. The anti-corrosion structure has no damage and pulverization phenomenon except for a small amount of dirty pollution and has the conditions for use in the marine high salt fog environment.

Strong Weather Resistance

During the service of offshore PV in open marine areas, due to the combined effects of high or low temperature, strong ultraviolet irradiation, high salt and high humidity, the anti-corrosion coating scheme is easy to age. Sungrow Floating PV technology team optimizes and controls the topcoat coating system, designs a high bond energy Si-O bond polysiloxane topcoat coating system, and alternately detects 3000 h + through fluorescent ultraviolet light and dark high humidity environment. Good elasticity, ductility and excellent high or low temperature resistance ensure the anti-corrosion structure's weather resistance and protect the power station's stable operation.

Environmentally Friendly

Most of the traditional paint coatings have toxic substances and irritating odors. Sungrow Floating PV follows an eco-friendly and sustainable development strategy. The main body of the coating in the anti-corrosion coating system uses a non-toxic and pollution-free ingredient formula. The coating material is fully tested by the TUV third-party authority to meet the EU ROHS environmental protection standards.

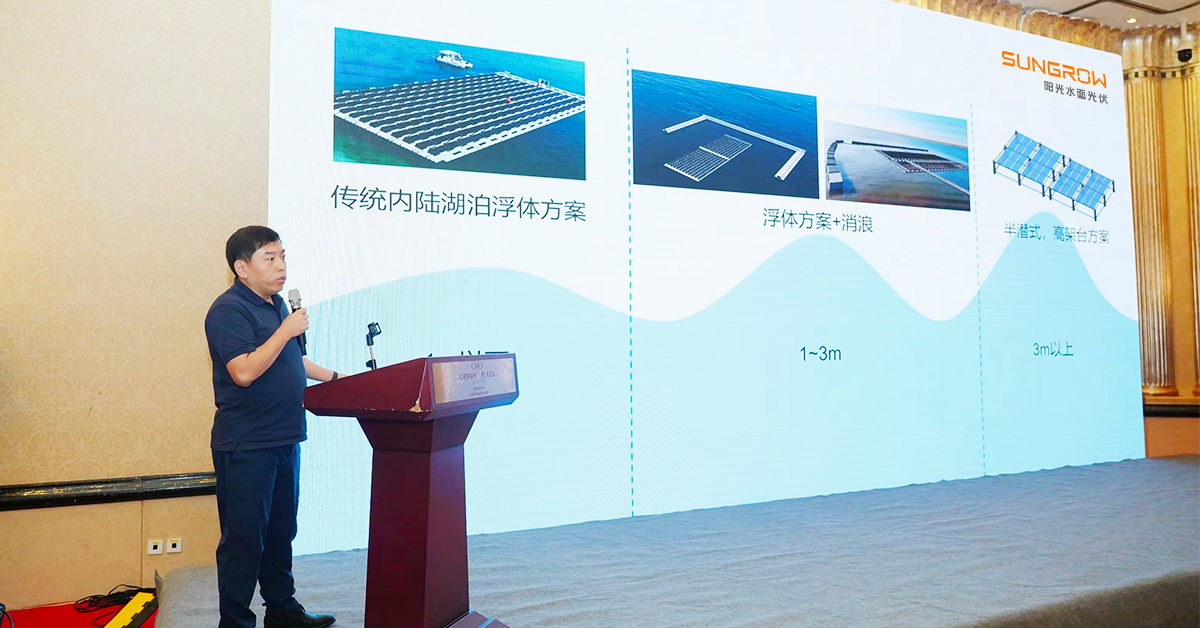

Practical Cases

In recent years, relevant provinces have successively introduced offshore PV support policies, and the market has gradually matured and improved. Offshore PV has become a key area in energy transformation strategies. However, in the process of practical application, there are still a series of technical challenges in offshore PV. Sungrow Floating PV has always firmly adhered to the strategic concentration of the technical route and the strategic endurance of continuous R&D investment, focused on market demand, and led the technological change of the industry, so as to ensure the long-term and stable value gain of customers.